When comparing ventilation systems, there are several aspects to consider. Here are eight advantages that are not so obvious if you have never seen a textile duct system before.

1. Costs

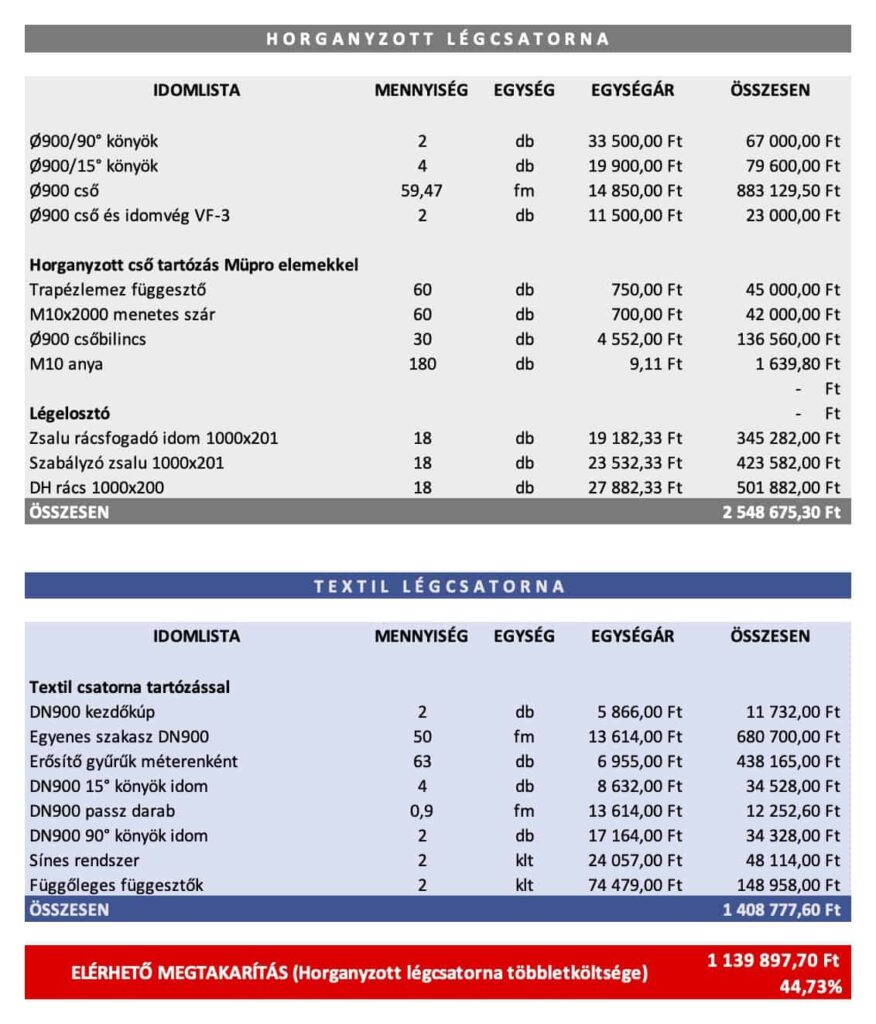

The comparison below shows the material cost of a textile duct system designed for a pressure of 150 Pa, optimised for the transport and uniform distribution of 18,000 m3/h of air, compared to a conventional metal duct system with the same characteristics.

In terms of dry figures, the following calculation is shown for the ét ventilation system:

On the basis of the above table, if the same system is used, the investment costs can be reduced by HUF 1 139 897 if the textile duct we manufacture is chosen, not to mention the other advantages of textile systems. In this case, the savings can be between 40-70% depending on the insulation.

2. Size

The ideal range of air velocity within a textile duct is between 7-8m/s, while conventional systems allow air velocities of 4-6m/s, depending on the branch and the application environment. This means that when using textile ducting, you can work with a smaller diameter, which makes your job easier.

3. Material handling

The comparative table also shows how much less items are required to install a given textile duct system compared to a spiral duct system.

What does this mean in reality?

- The procurement process is simpler.

- It can be transported in a station wagon or a mini van with a roof rack, while a conventional spiral-coated system requires a van to deliver the pipes, insulation, threaded rods and C-rail brackets to the site.

- Many ventilation engineers cannot insulate well, so a separate insulation team is needed, which requires extra organisation, time and cost.

4. Installation time

As our own textile duct systems consist of 3 main components (fabric duct, track and hanger), they can be installed with less manpower and faster than conventional systems. The main reasons for this are:

- less material handling time,

- no prefabrication on site,

- you don't need to throw anemostats at it,

- you don't need to adjust your anemostats,

- do not need to be insulated.

5. Mass

The textile air duct branches are made of textile and the corresponding rail suspension is made of aluminium. This is why they weigh a fraction of the weight of galvanised ducts.

Thanks to their light weight, textile air ducts can also be fixed to lightweight structures or even in a semi-circular shape to the profile of a suspended ceiling grid.

6. Aesthetics

For 99% of people, the quality of the built environment around them is a major contributor to their well-being. The textile air duct can play a significant role in this, and can also be adapted to the company's image and design, thanks to its wide range of colours and shapes. In a traditional spiral-coated system, we see either black Armaflex insulation or galvanised ductwork, which limits our options.

7. Air distribution

Perfect air distribution is one of the biggest advantages of textile duct systems - only with a carefully sized system. Through the many tiny perforations, air flows out of the duct evenly and draught-free. Of course, this can also be achieved through a traditional spiral-cored anemostatic system, but it is much more difficult and cumbersome. Our experience is that since all anemostats are adjustable, someone is bound to touch them at some point. This, in turn, upsets the air balance and can create a draught effect at the other inlets. This is unthinkable with textile ducting.

8. Maintenance

We can't imagine how much dirt or dust can accumulate in an air handling system over the years of use, even if the filters in the air handling units are regularly maintained. In contrast, textile ductwork can be easily removed, washed in an industrial washing machine and easily replaced after drying.

So, in short, our textile duct systems offer the following advantages over traditional spiral capped insulated ducts with an anemostat:

- 70-80% cheaper alternative

- a smaller diameter to allow the same amount of air to enter a room

- easier to transport, handle

- faster to assemble

- a lightweight technical solution and does not place a significant load on the roof structure

- improves well-being and appearance

- draught-free

- washable

Click here to see where textile ducting can be used as an air conditioning solution.