This statement was made at the 8th Air Conditioning and Ventilation Trade Day and we fully agree with it, with the proviso that the textile air duct is already one of the most significant innovations of the present and as such has the potential to provide ideal working conditions in many applications.

The EXANDAIR draught-free textile air duct is manufactured as part of DAAL GROUP, another industrial design and construction company of the group, as Dániel Sándor, managing owner of DAAL GROUP, is also committed to creating quality and energy-efficient working conditions. Our goal is to implement technological engineering systems efficiently and accurately, so we work with a design and manufacturing background that allows us to burn out everything to the maximum in time and quality.

.

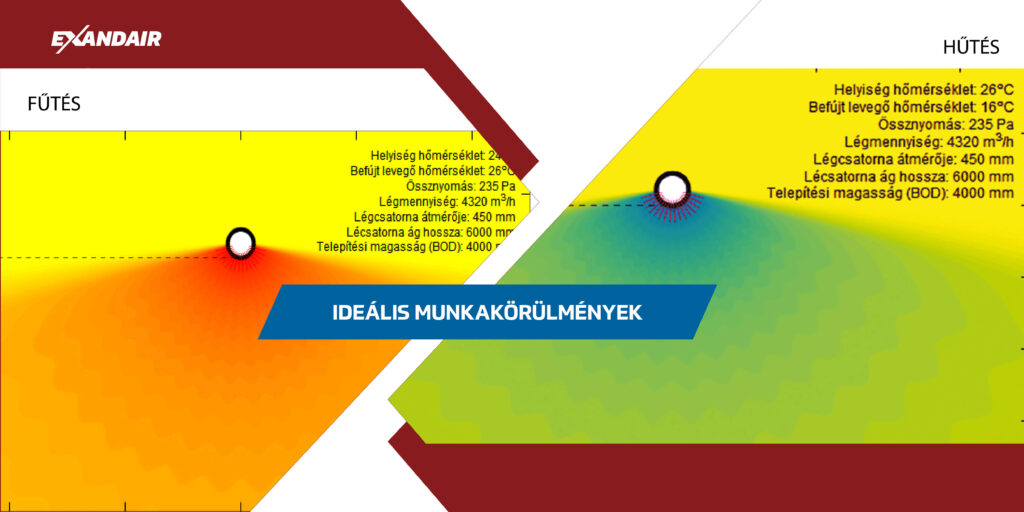

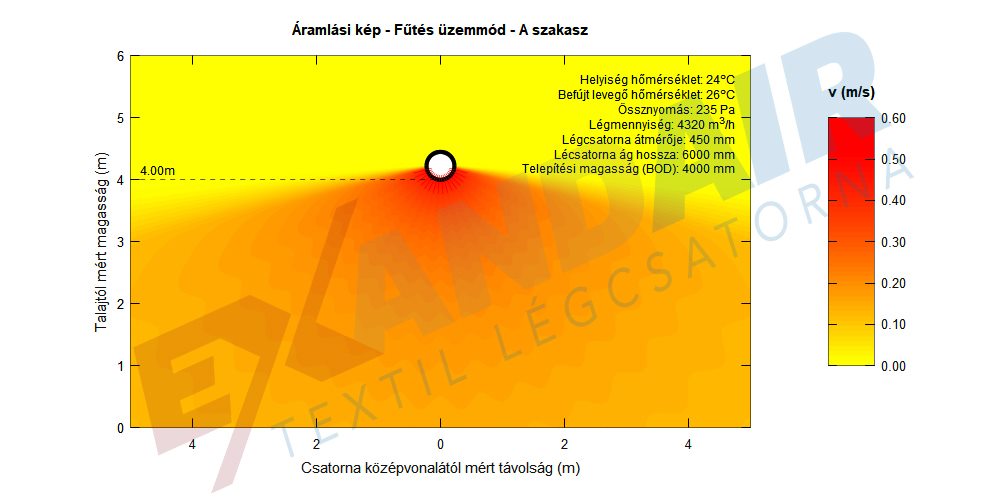

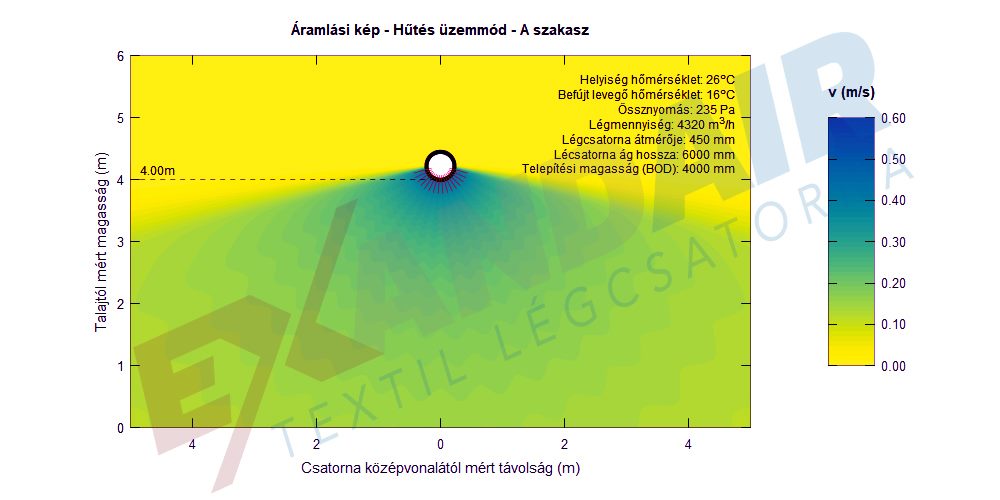

Software and simulations help to produce draught-free textile air ducts

We have developed our own scaling software together with the Budapest University of Technology and Economics and are currently continuously improving it to offer new possibilities. Thanks to this, EXANDAIR textile air ducts can also be manufactured and tested to meet specific requirements and then put into production.

- in different forms,

- in different colours and

- in different materials

- in different fire resistance classes,

- with hanging according to the needs of their customers,

- striving for the optimal solution.

.

What does it mean?

When designing the working environment and working conditions, the right temperature and air distribution are of paramount importance, as a poorly designed system will result in a draughty space and poor air circulation. To avoid such negative consequences, it is important to focus on the selection of the right textile duct material and its accurate design. This is where we come in.

.

We place great emphasis on research to create the ideal working environment

EXANDAIR is the only company in Hungary that manufactures textile air ducts and invests heavily in research and development. That is why we submitted an application for support under the call for proposals "Promotion of corporate research, development and innovation activities", where the Ministry of Finance considered their application for support "Implementation of textile air duct systems" as eligible.

As a result, we are now working with the Department of Fluid Mechanics at the BME to develop our latest innovations to meet the needs of the market for newer and newer working environments, and to enable the best working conditions at the best possible value for money.

The Department of Fluid Mechanics at BME is participating in the project with theoretical background, measurement techniques and computer simulations (CFD), which will enable the new, extended EXANDAIR textile duct family to be supported by CFD simulations to produce systems that are even faster, easier and simpler to install and maintain.

.

Increased comfort, savings can be between 40-70% depending on the insulation

The energy efficiency of our textile duct systems is constantly increasing thanks to improvements, so we can also reduce our ecological footprint, where we are replacing metal and using recyclable polyester fibres.

We draw on a research and development background in electrical engineering, acoustics and manufacturing technology

- increased energy efficiency in air transport,

- more efficient fresh air intake,

- minimise the draught effect,

- low-noise operation and

- achieving maximum cost and time efficienc

- to achieve the ideal working conditions.

Thanks to the simulation system mentioned above, we are able to meet our customers' needs, from conceptual design to implementation, because our mission is to provide our partners with draught-free, evenly distributed EXANDAIR textile air ducts to ensure better air quality in the workplace and a better working environment at the best possible

Take a look at our case studies to learn more about the benefits of textile ducting systems, their many applications and contact us. Follow us on our Facebook page for instant updates.